"BJohnson11" (brettjohnson01)

"BJohnson11" (brettjohnson01)

01/02/2015 at 16:44 • Filed to: None

3

3

8

8

"BJohnson11" (brettjohnson01)

"BJohnson11" (brettjohnson01)

01/02/2015 at 16:44 • Filed to: None |  3 3

|  8 8 |

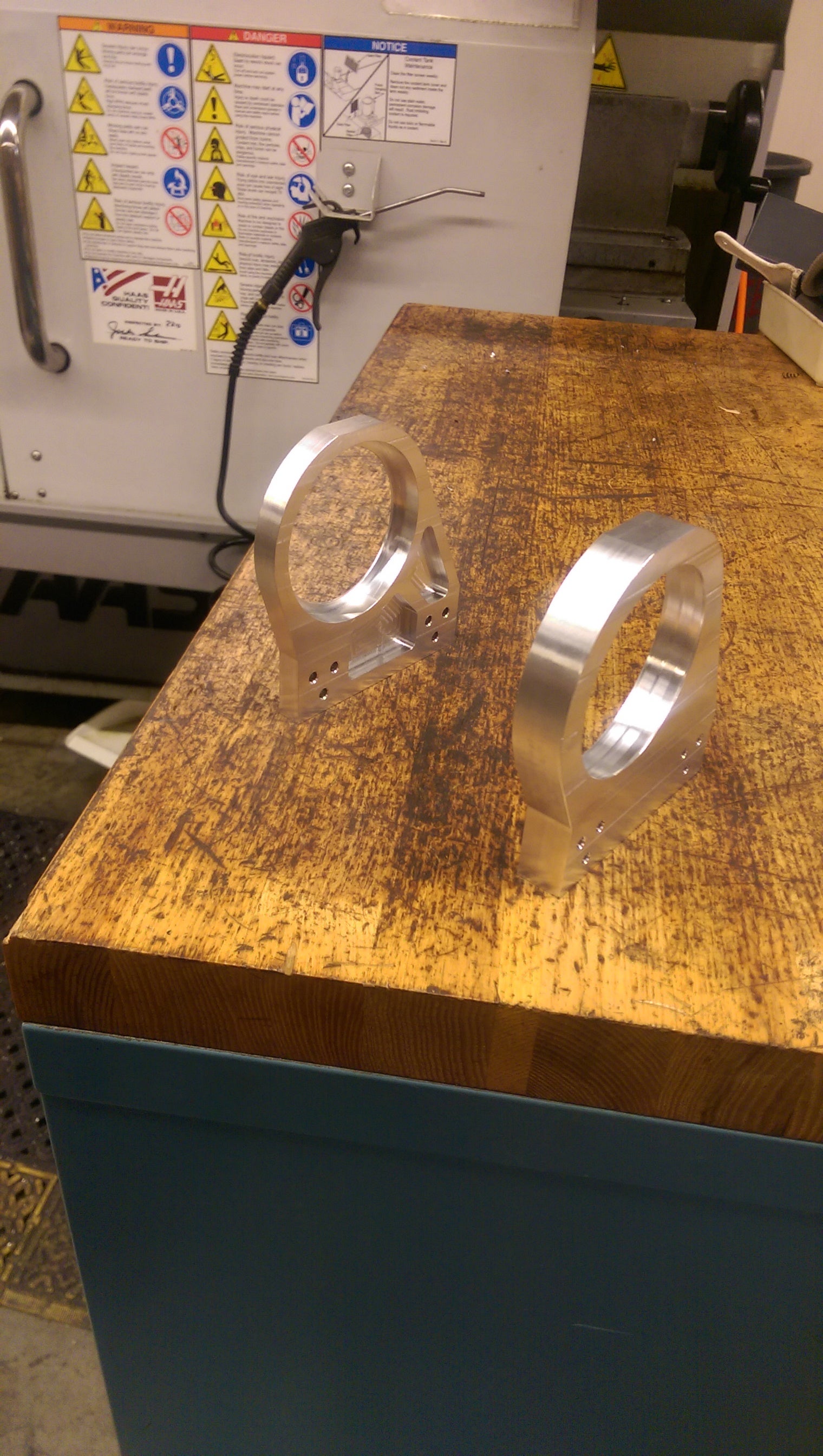

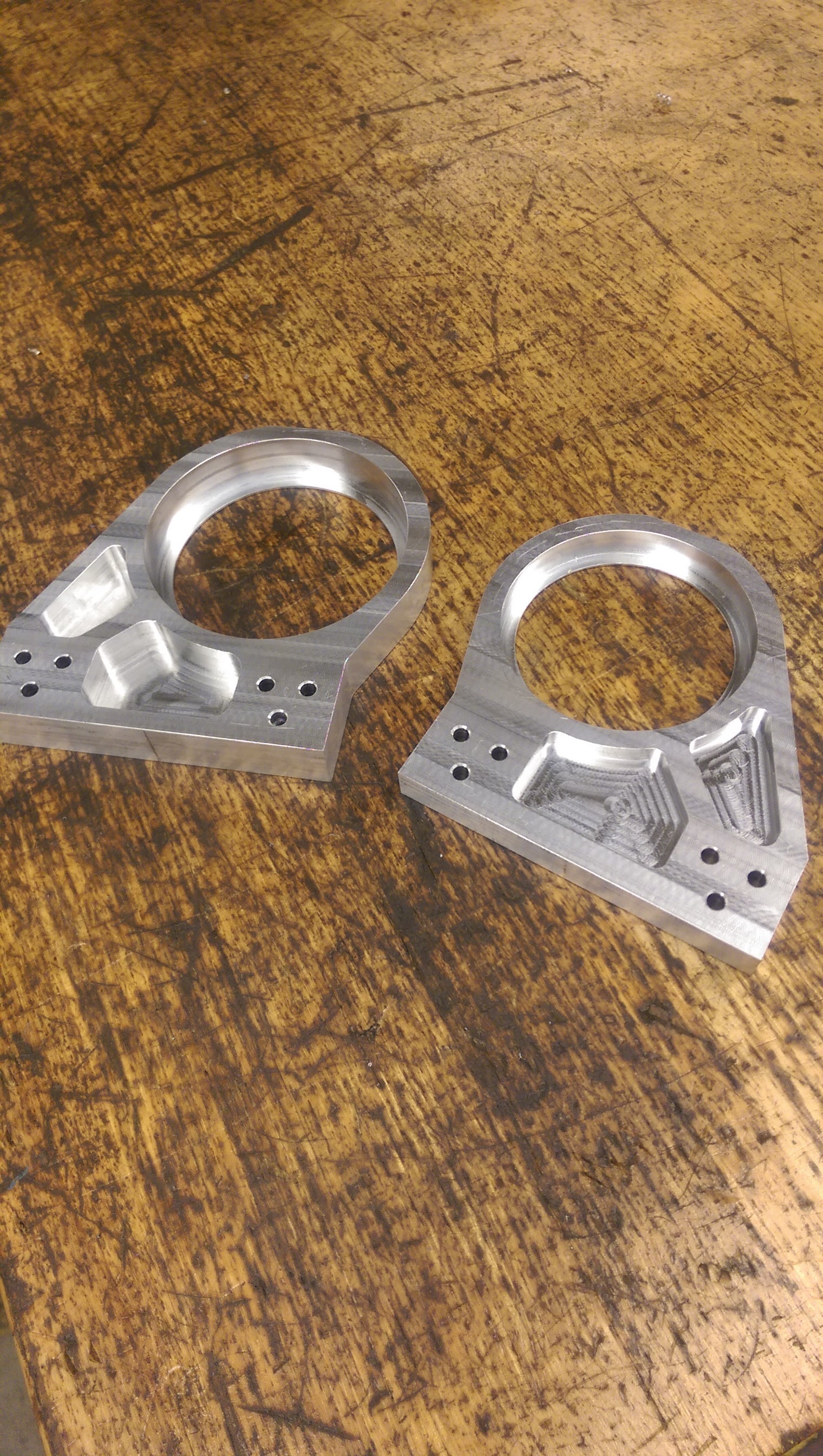

Cranked these out on the Haas Mini Mill. They're mounts for the differential. Bearings press into those big bores, then the part presses onto the differential, and the whole unit gets bolted to the subframe. This means that all my work for the differential subsystem is done, and I just have to focus on the wheel hubs and all those components.

RWS Motorsport

> BJohnson11

RWS Motorsport

> BJohnson11

01/02/2015 at 16:48 |

|

Orf, those are rather pretty :D love abit of CNC work.

Will you be getting them anodised before they get mounted up? because there is some serious tart potential there.

BJohnson11

> RWS Motorsport

BJohnson11

> RWS Motorsport

01/02/2015 at 16:51 |

|

Probably not. Once I get the hubs done, I'll probably get those anodized, so we might throw these in with them. Wasn't really planning on it though.

RWS Motorsport

> BJohnson11

RWS Motorsport

> BJohnson11

01/02/2015 at 16:56 |

|

Id be inclined too. It makes a surprising amount of difference to how they will hold up with bearings in them (nearly wrote bears... i doubt anodising would help against bears).

plus, i mean, shiny :D

I got a load of stuff (well 8 bits) anodised for my final project at university, and i only got charged like £10 a part.

Out of interest, whats it being attached too? (car wise, rather than diff etc :) )

BJohnson11

> RWS Motorsport

BJohnson11

> RWS Motorsport

01/02/2015 at 17:08 |

|

Formula SAE car.

RWS Motorsport

> BJohnson11

RWS Motorsport

> BJohnson11

01/02/2015 at 17:51 |

|

oOOo very nice. Really wish I'd gotten involved in my unis racing team. Didn't do engineering, only did industrial design, but so cool.

Good luck with the build, look forward to more oppo-updates

Levitas

> BJohnson11

Levitas

> BJohnson11

01/02/2015 at 18:49 |

|

Those look pretty awesome! Not a big fan of the MiniMill, much more a VF2SS kind of guy.

As a side note, as a machinist at Purdue who has done quite a bit of work with all of the SAE teams wanting things for bearings being machined: did you measure the size of the pocket and check the fit before pulling it from the machine? I've had a number of headaches because someone pulled a part before checking the fit, and they come crawling back to me because their bearing won't fit :\

I think I've posted some of my SAE-related CNC work before, I should post some more machining porn.

uofime

> BJohnson11

uofime

> BJohnson11

01/05/2015 at 12:04 |

|

how is the team tensioning the chain?

Most teams have moved to eccentric carriers now, which this isn't, also it doesn't look like these would mount to turnbuckles either with is the other usual solution.

BJohnson11

> uofime

BJohnson11

> uofime

01/05/2015 at 18:28 |

|

spacers between the subframe and these mounts. Much more rigid and easier to make sure the bores are aligned than turnbuckles. That way all the load from chain tension is sent through the mount and directly through the subframe instead of through a turnbuckle.